Although the 2-stroke engine looks more simple than 4 stroke engines, with very few components, only the piston within the cylinder, but the real 2-stroke engines are very complex in the calculation: The main advantage of motion dynamics of gas in the engine to generate power. There are different phases that are very influential in the crankcase and cylinder block in at the same time, so that machine 2 is not able to work more efficiently (just enough 360-degree crankshaft rotation, compared with 720 degrees of crankshaft rotation by engine 4 stroke) is what causes the explosion 2-stroke engine power than the 4 stroke stung. The secret power of the engine 2-stroke is the primary and secondary compression settings in the machine.

This is why we often recommend in rat rider if you want to send the machine to work with all engines or motors should be packaged and gentlemen, because not enough just to block or head modification alone. Let us observe the workings of 2-stroke engines in the gas dynamics:

1) Beginning of the piston is at top dead point (TDC, zero degrees crankshaft), sparks begin to crack and spread the gas in the combustion chamber and push the piston down as the initial step of business. The driving force is pressing the gas piston into the crankcase to cause petal open. Compression on the crankshaft is necessary to generate suction force on the reed valve, moreover assisted membrane such as v-Force reed valve with a lot so even though the compression is low fresh gas mixture can be easily entered. At an angle of 90 degrees crankshaft, and pistons are in the maximum negative acceleration, the exhaust port is open as a sign of the end of the business step. Hot gas is wasted by itself out into the exhaust. Compression on the crankshaft begins to weaken when ported to transfer began to open. The pressure in the cylinder should be reduced lower than the pressure in the crankcase with the aim that unburned gas can out of the transfer ports during the flushing.

2) Transfer ports open about 120 degrees before lower dead point (TMB). Flushing begins. This means that fresh gas out of the port transfer and fuse to form a cycle. Gas will move upwards toward the back of the cylinder and rotates continue rinsing residual combustion gases from the power stroke. It is important that the rest of the combustion gases must be removed completely, to open the room for a mixture of fresh air into the combustion chamber. That is the key to making big power p

Gas will move upwards toward the back of the cylinder and rotates continue rinsing residual combustion gases from the power stroke. It is important that the rest of the combustion gases must be removed completely, to open the room for a mixture of fresh air into the combustion chamber. That is the key to making big power on two-stroke engine. More and more capable of fresh gas in the compression on the dome of the combustion = more power is created!

Now the fresh gas also wasted until the header at the exhaust. But the fresh gas is not going to get away with it because the compression pressure wave has a reflection of the design of the exhaust pipe tip is good, to bring back a package of fresh gas into the cylinder before the piston closes the port hole. This is the uniqueness of SUPER CHARGE effect on 2-stroke engine. From here see the importance of 2-stroke exhaust design, calculations done to reduce the trial n error is needed. The main advantage of 2-stroke engines is that they are able to burn more air / fuel than the engine capacity is calculated through the calculation. An example: 125 cc 4-stroke engine is probably only able to burn a mixture of 110 cc of air / fuel in the cylinder, with 88% efficiency of the manufacturer (probably lower than that) while the 2-stroke 125 cc engine might burn a standard 180cc air mix- fuel inside the cylinder. Being able to see the difference? Can make a picture of how to design the engine 4 is not able to fight for 2-stroke motorcycle engine?

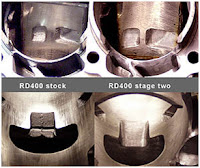

ported 2-stroke

3) Now the crankshaft has berputah past the bottom dead point (180 degrees) and the piston upstroke embarked. Compression waves that bounce off the exhaust pipes to bring fresh gas back through the exhaust port (now also serves the inlet port is not it?) As the piston closes the port, the compression begins. In the crankshaft, the pressure becomes lower than atmospheric pressure, causing a vacuum and this will open the suction valve reed and put fresh gas into the crankcase.

4) The gas is not burned will be depressed and some time before the piston reached TDC, the ignition system will meletikkan sparks and start the ignition process. And the cycle will continue to repeat.

Learn how to process basic 2-stroke engine works. When was ported from the open and closed in crankshaft degrees duration, our modifications will undoubtedly be on the right path.

0 komentar:

Posting Komentar